【Origin Pic】 |

¥10.30/kg-10300/Ton |

【Origin Pic】 |

¥10.30/kg-10300/Ton |

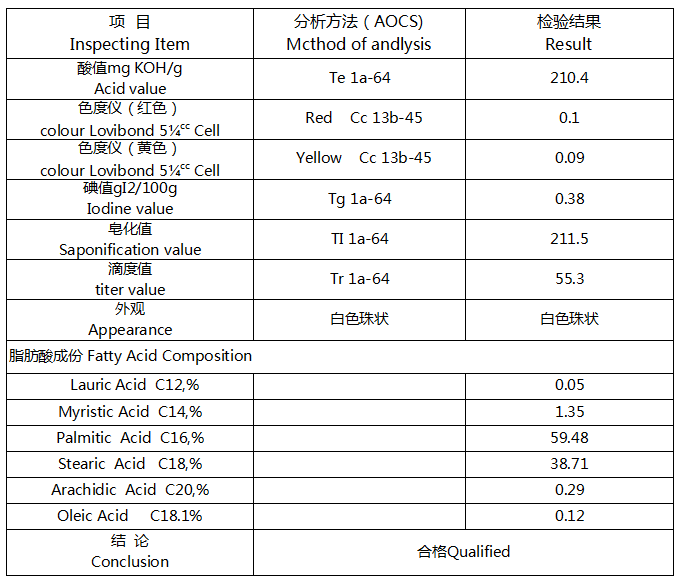

Stearic acid is prepared from imported palm oil after catalytic hydrogenation, high pressure hydrolysis, fatty acid dehydrogenation, and vacuum distillation. (High pressure hydrolysis: no catalyst is required, the hydrolysis period is about 5 hours, the conversion rate is basically 98-99%, and the production is continuous. The obtained stearic acid has good color and luster, high content and few impurities. Add decomposition to the hardened oil. and then hydrolyzed to obtain crude fatty acid, which is then washed with water, distilled, and decolorized to obtain the finished product. At the same time by-product glycerol.

Plastic Industry:

(1) Heat stabilizer for the production of stearate.

(2) Lubricant is a good external lubricant.

(3) The release agent can form a thin layer of high-efficiency isolation film on plastic products.

Rubber industry:

(1) Vulcanization activator, which promotes the vulcanization speed, shortens the vulcanization time, reduces the vulcanization temperature, and improves the physical and mechanical properties of the rubber.

(2) Softener can reduce the sticking phenomenon during kneading, help to disperse carbon black, and improve wear resistance.

Candle production, textile dyeing and finishing industry, paper industry, stationery, calcium carbonate industry, brightener, etc.

Contact:

+86 13662789083/Miss zhengContact:

+86 13620073040/Mr. QianAddress:

Dongguan City Zhongtang Town Daxinwei RoadAbout us

-Company Profile -Company image -Video -Customer -Contact usProduct

-Plasticizer -Stabilizer -CPE -Stearic acid -More...Applications

-Resin tile application -Pipe and Fitting Application -Profile application -Cosmetic application -More...News

-Knowledge -Industry -QuestionMobile terminal

WeChat QR code

Applets